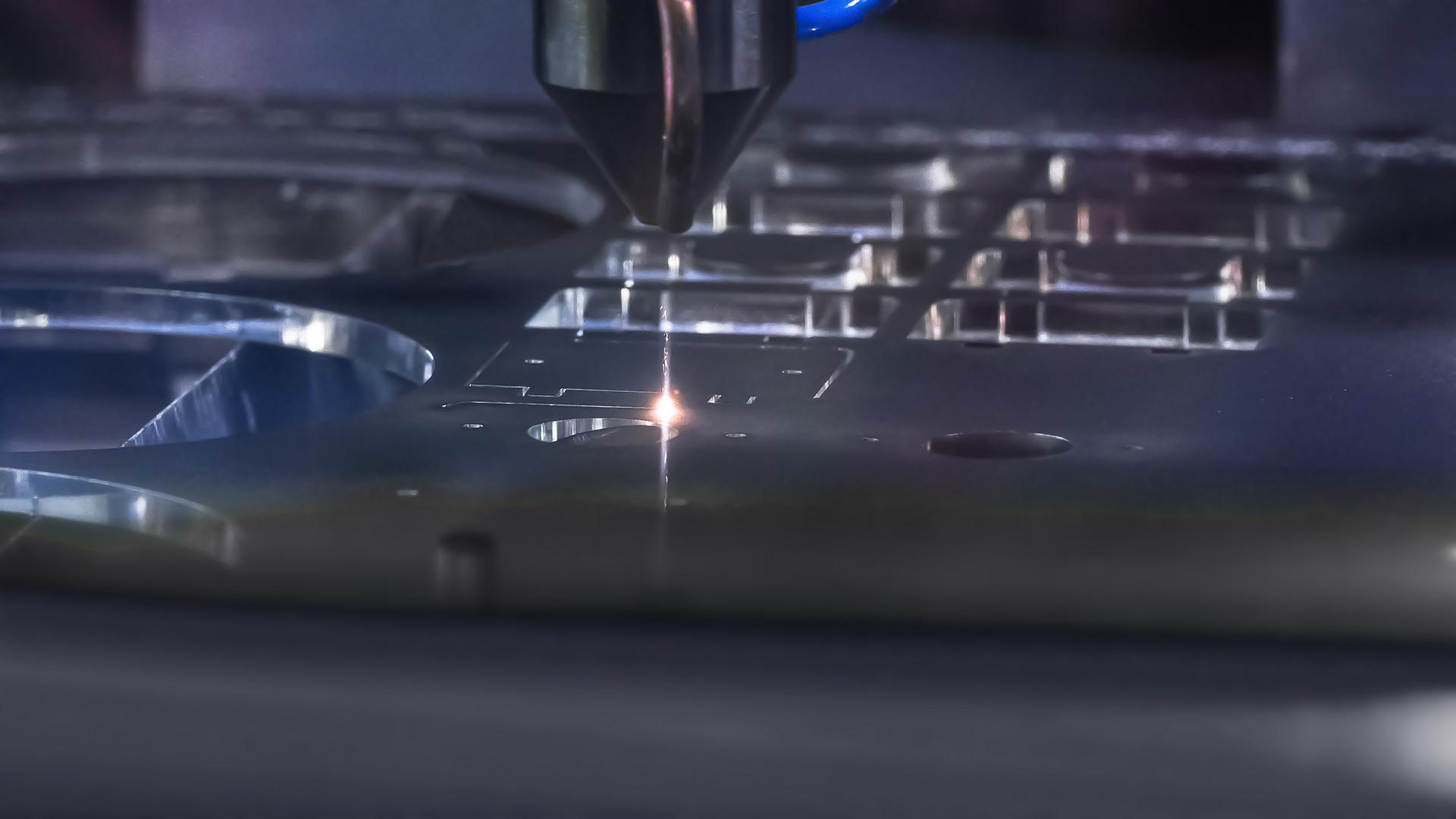

Gravotech's lasers worden veel gebruikt in industriële en niet-industriële omgevingen, voor het markeren, graveren, verfraaien en snijden van elk materiaal, van plastic tot metaal, tot keramiek, tot organische materialen, enz.

De beheersing van verschillende laserbronnen (Fiber, CO2, Groen, Hybride) stelt ons in staat te voldoen aan alle behoeften op het gebied van identificatie, traceerbaarheid, personalisatie en signalisatie met een uitgebreid gamma standaard en op maat gemaakte lasermachines.

The differences between laser engraving and marking

Laser marking and laser engraving are techniques frequently used to personalize items, provide signage, or mark parts in industrial processes. Their major advantage: high efficiency on a variety of materials, for long-lasting, aesthetic results.

However, they differ in several respects: interaction with the material, appearance, and durability of the result.

- Laser marking involves marking logos or inscriptions on a material by heating it to its melting point.

- Laser marking is particularly well suited to surface treatments because of its superficiality.

- Its high precision makes it ideal for small characters and detailed patterns.

- It is also highly resistant to heat and corrosive substances.

- This technology promotes increased productivity thanks to high marking speeds.

- This technique involves vaporizing the material deeply onto the surface to be engraved.

- Laser engraving uses a powerful laser beam to remove the top layers of material by sublimation (transforming it from a solid to a gaseous state).

- The depth of the engraving can vary depending on the material, the power of the laser, and the amount of material evaporated.

- Despite a longer engraving time, it offers greater durability thanks to the engraving depth.

- It is compatible with projects requiring a certain degree of wear resistance.

Wat zijn de voordelen van lasergraveren?

Contactloze lasertechnologie overwint de hardheid van de onderdelen en maakt een zeer fijne markering met hoge snelheid mogelijk. Het werk is zuiver en onuitwisbaar.

- Flexibel, lasermarkeren is geschikt voor alle soorten productie, van esthetisch graveren tot graveren op het hoogste industriële niveau.

- Hij is economisch en milieuvriendelijk en gebruikt geen oplosmiddelen, inkt of andere chemische producten voor het snijden en graveren.

- Laserprocessen zijn gemakkelijk te automatiseren en besparen tijd, energie en materiaal in vergelijking met traditionele processen.

- De lasergraveermachine is een geweldig instrument om uw productiviteit en uw imago te verbeteren en biedt oneindige creativiteit.

* Definitie: Engels acroniem "Light Amplification by Stimulated Emission of Radiation". Bij uitbreiding: apparaat dat een zeer krachtige straal uitzendt op basis van het lasereffect.

Laser engraving and laser cutting: case studies

Welke laserconfiguratie zal aan uw behoeften voldoen?

Omdat elk bedrijf uniek is en op een andere manier werkt, worden deze technologieën in verschillende configuraties aangeboden:

In-line integreerbare uitrusting

- Robuuste en gemakkelijk te integreren lasermarkers, met volledige deskundige ondersteuning rechtstreeks van de fabrikant

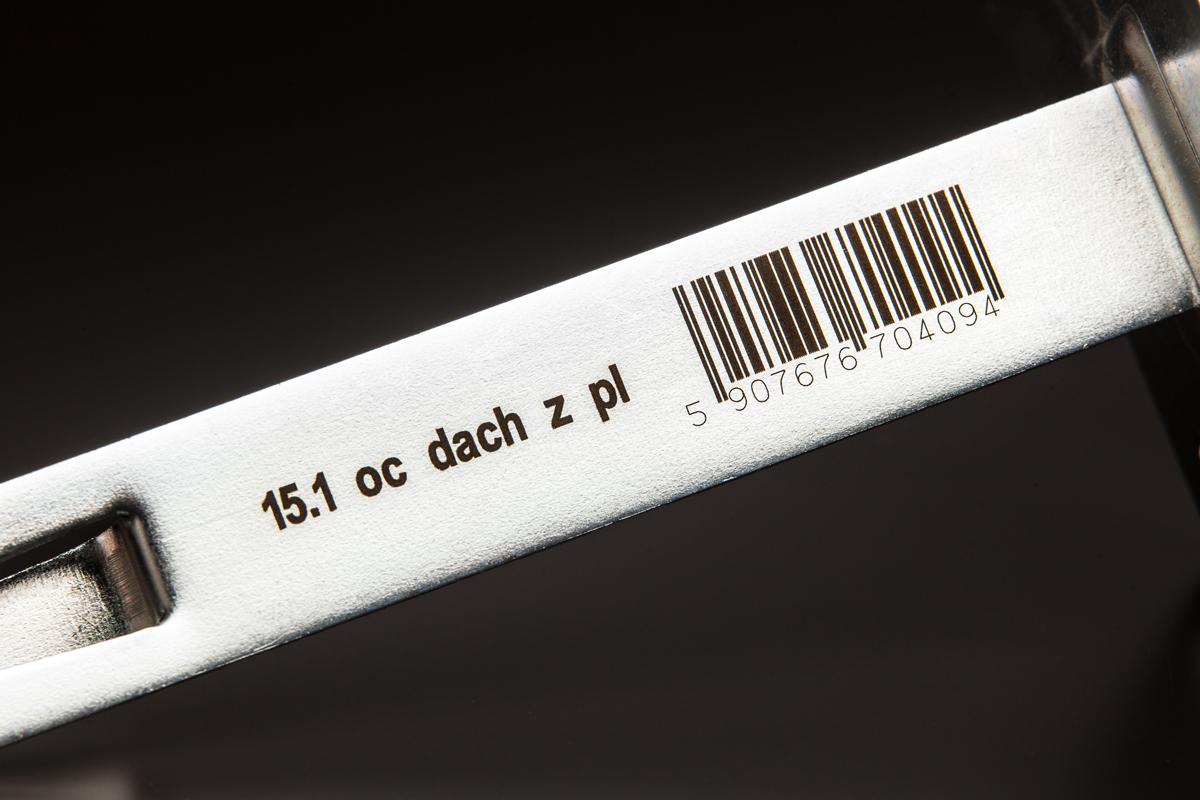

- Het systeem kan communiceren met uw omgeving en identificeert elk onderdeel met serienummers, logo's, tekst, Datamatrix™-codes, barcodes, QR-codes, datum- en uurgegevens

Autonome oplossingen

- Klasse I behuizing voor volledig veilige werking, ergonomische en zeer productieve tafelmodel lasergraveermachines

- Semi-automatische werkstations kunnen worden aangepast aan de meest veeleisende toepassingen

- Aangedreven door intuïtieve speciale software, heeft de operator in een paar klikken toegang tot alle traceerbaarheids- en creativiteitsfuncties

Leer meer over lasertoepassingen

Gravotech kan u helpen de beste oplossing voor uw toepassing te kiezen! Gravotech werkt samen met de meest erkende fabrikanten en onderdelenfabrikanten in de automobiel-, fijnmechanica-, medische, luchtvaart-, juwelen- en horlogerie-, elektronica-, gereedschap-, olie- en gassector en met professionele graveurs, enz.

Laser is ook ideaal voor het graveren op heel wat materialen zoals metalen, plastics, keramiek, glas, rubber, organische materialen zoals leder, hout en stof, enz.

Gravotech kan u helpen de beste oplossing voor uw toepassing te kiezen!

Fiber laser

Fiber lasers involve guiding light and the booster pump through glass fibers (fiber lasers). This technique enables high-resolution engraving thanks to the quality of the beam and optimal focus (precise focus).

On the production side, fiber lasers offer efficient cooling and a compact structure.

The MOPA laser

The MOPA laser can imitate the long pulse of conventional fiber lasers as well as the short pulse of conventional solid-state lasers. It enables marking of equivalent quality, with a faster process.

This technology is compatible with many projects. And for good reason, reactions are moderate (burning, melting, heating, etc.).

Laser engraving on different materials

Not all materials and laser sources are compatible with each other, depending on whether they are organic, plastic or metal.

For marking organic materials, we prefer CO2 laser sources, and the same goes for our plastics (Gravoply) or PMMA, which can be cut and engraved with CO2. For metal marking, the best source(fiber or hybrid laser) will depend on the desired result.

Laser engraving on metal produces a permanent, high-contrast marking without damaging the material.

For this type of project, we recommend using a raw, anodized, painted or plated metal surface.

Laser engraving on glass can also be used for personalization projects (window dressing, glass panels, etc.).

The technique owes its popularity to the quality of the rendering, which enhances the object without damaging the material.

The different types of laser engravers

Different types of laser engravers are available to suit all applications and uses. For example, the need is not the same for a production line, a workshop, or an independent store.

We therefore distinguish between galvanometric technology, used in laser stations and integrable lasers, and gantry technology, used in laser tables. This difference makes it possible to adapt to production environments and the size of the objects to be engraved.

The laser station, an equipment that can be adapted to any space, from the factory to the store.

Laser stations use galvanometric technology, with 4 different laser sources:

- fiber,

- DPSS (hybrid and green),

- CO2.

Engraving is achieved using a set of mirrors that reflect laser beams at very high speed.

They can be used in a wide variety of settings like factories, robotic cells, workshops, offices, independent stores, etc.

This type of engraver is fast and precise, mainly for marking and engraving small objects.

The laser table, compatible with small spaces

Laser tables engrave line by line along 3 axes: horizontal (X), vertical (Z) and depth (Y). This technique ensures clean cutting or engraving.

The laser tables offered by Gravotech feature a CO2 or fiber source, or both in the same laser table.

They are compatible with smaller spaces such as a workshop, factory, office or store.

This is a slower type of laser engraving machine, lacking in precision but offering a large marking area.

Laser integration for production lines

Integrable lasers use galvanometric technology.

4 laser sources are available from Gravotech:

- fiber,

- DPSS (hybrid and green),

- CO2.

Generally speaking, these laser engravers are used in industry (production lines, factories, robotic cells...) to mark parts. The goal is to mark for identification and traceability.

Which laser engraving software is the most suitable?

To drive these different laser engraving machines, you need laser engraving software with, CAM (Computer-Aided Manufacturing) functionality and a controller. These are essential to create your toolpaths, control the machine, and send it your command file (G-code). You can also use CAD (Computer Aided Design) or DAO (Computer Aided Drafting) software to design, draw, and specify your patterns and texts to be engraved.

At Gravotech, 3 software packages are available to manage your laser or integrable table or station:

- Gravostyle™: the engraver's toolbox for exploring all design possibilities.

- Lasertrace: the industrial software for marking traceability and identification (excluding laser tables).

- Gravotouch™: the software designed for use on a tablet in the store, featuring a modular, fully customizable digital interface, ideal for beginners.

From machine technologies and solutions, laser engraving is integrated into a dense environment. Today, laser engraving is compatible with a wide range of materials, needs, and applications, guaranteeing results adapted to every type of project.

Would you like to find out more about our laser engraving machines? Gravotech's team of experts can answer all your questions.